Combined with GELDRIVE™ fast loading delivery systems, STEMGEL™ provides effective blast containment and consistent stemming control in every blasting sequence.

Contact our team for more information

Effective Blast Containment

STEMGEL’S™ powerful energy-attenuating properties result in 98% of blast pressure being attenuated and reflected back into the formation from the stem deck. This results in higher oscillating pressure waves with greater max positive pressure than aggregate stemming.

The outcome in Open Cut situations is a better controlled blast with substantially increased micro fracturing and breakage.

Blast holes stemmed with STEMGEL™ hydrogel result in the ejection of water vapour. The overall damping effect of STEMGEL™ when coupled with the explosive and walls of the blast hole, decreases noise, dust and air over pressure vibrations, resulting in a water vapor ejection and minimising fly rock risk.

Consistent Stemming Control

The consistency of the hydrogel matrix in STEMGEL™ also enables engineers to determine a constant value from the pressure wave attenuation and reflection.

When replacing aggregate as stem, STEMGEL™ can be loaded with lower stemming deck horizons so that users can recalibrate the depth of burial levels to increase the height of the explosive in the hole and decrease the stemming deck, all while achieving greater fragmentation.

SHOCKWAVE’s Specialised GELDRIVE™ dose units will deliver STEMGEL™ into a blast hole up to 50 metres from the truck making it ideal for stemming contour and pipeline blasting.

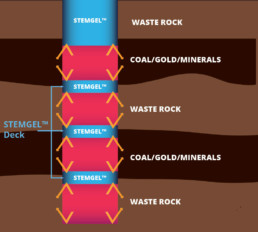

Strata Decking

STEMGEL’S™ powerful attenuating properties make it effective for Strata Decking where a layer of STEMGEL™ between explosive layers, provides a ‘constant’ material that successfully attenuates pressure waves resulting in greater control and accuracy at each layer of the formation.

Down Hole Water Control

DHDA Down Hole Dewatering Agent solves down hole water and dynamic water ingress easily and acts as another layer of energy-attenuating stem to further increase the effectiveness of a blast.

Suitable for a toe stem deck, a level and accessible bench for the next drill and blast process.

SHOCKWAVE stemming solutions have been proven to deliver:

Simple stem loading

Consistent stemming results

Greater blast control

Easy and successful Wet Hole management

Significant Noise and Dust reduction

Effective contour blasting

Effective hot hole stemming

Successful stemming of production applications for all mineral types

Advancing Drill & Blast like never before.

Contact the SHOCKWAVE team for more information.