WBI 2024 Countdown

October 7-9, Shockwave Gel Technologies will be exhibiting at the WBI 2024 World Blasting Innovators Conference in Porta, Portugal.

WBI is the bringing together of mining professionals from across the globe, who are committed to making the world a safer, more efficient, and more sustainable place. Organisers and participants follow the mantra that through innovation, collaboration, and education, the science and practice of blasting can be advanced so as to create a future where Drill&Blast is a force for good.

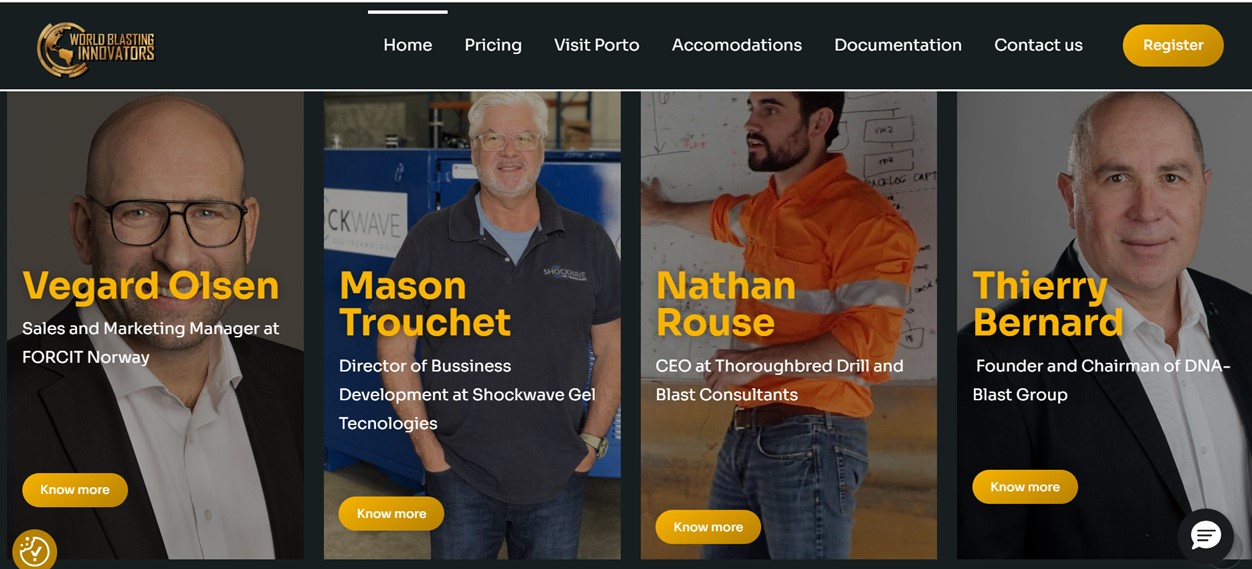

Shockwave director of business development, Mason Trouchet, will be presenting Monday 7th at 3pm local time on the science and innovation of hydrogel stemming, as well as launching the new StemGun, custom designed and recently launched by Shockwave to revolutionise stemming underground.

If you’re going to be at WBI 2024, please head to Stand 10 and connect with Mason as well as Shockwave MD, Damien Browne.

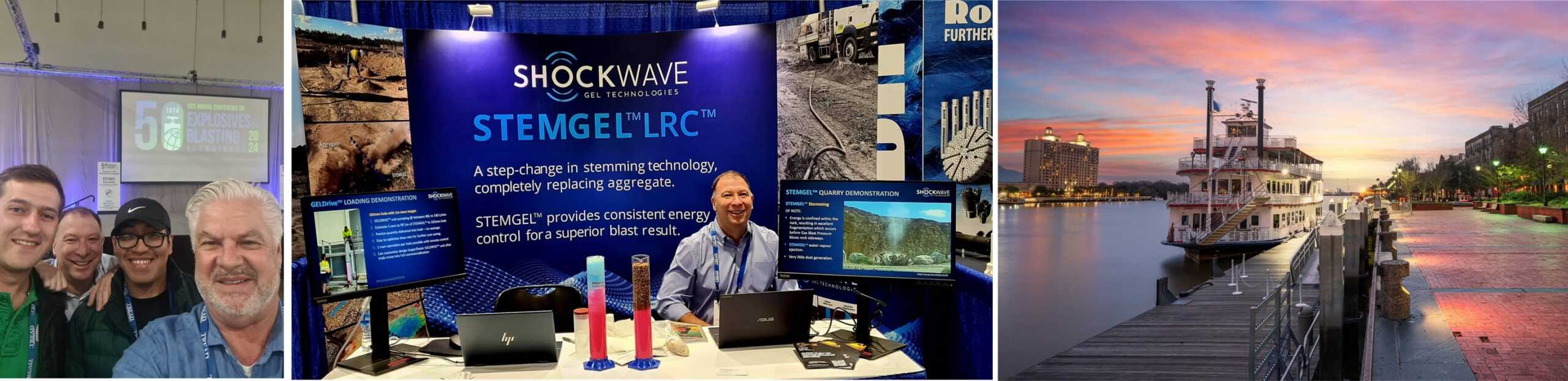

Shockwave Exhibits at 50th ISEE Annual Conference in Savannah, Georgia USA

January 2024 saw Shockwave MD, Damien Browne and Business Development Manager, Mason Trouchet cross the pond for Savannah Georgia, USA. The trip was to exhibit Shockwave Gel Technologies and STEMGEL at the 50th ISEE Annual Conference on Explosives & Blasting Technique held at the palatial Savannah Convention Centre on the vibrant banks of the Savannah River.

The event brought together some of the world's leaders in Drill and Blast and the lads were kept super busy sharing all there is to know about STEMGEL with delegates from across the globe.

After making valued connections, the event sees Shockwave working toward projects across the US as well as South Africa, Brazil, France, India, Mexico and Mozambique!

Where next? Stay tuned for updates!

Shockwave offers greener, better blasts with STEMGEL™ innovation - Mining Magazine

A Western Australian innovation is making the drill and blast process safer, more efficient and more environmentally friendly – and Shockwave Gel Technologies is keen to help more mine sites improve thanks to its patented STEMGEL technology.

Shockwave Executive Director of Business Development Mason Trouchet likens the company’s product, STEMGEL™, to ’solid water.’ “ STEMGEL™ is a hydrogel that brings vastly improved stemming consistency and valuable environmental improvements compared to aggregate stemming.”

While there have been developments in the drill and blast space over the years, particularly in detonator technology and explosives, Shockwave has tackled “the missing link” – the often-overlooked stemming process.

Typically, miners stem a hole that’s been drilled for explosives with aggregate or cuttings – filling the hole around the detonator cord with crushed rocks to cork or contain the blast gas energy. Aggregate however has no effect on control of the pressure wave energy which is key for effective rock fragmentation.

“Most engineered Drill and Blast elements – the drilling, the detonator control, the explosives – are consistent, but then you have this one outlier of aggregate rock at the top of the hole. Our solution to that is STEMGEL™ - a hydrogel, which is more effective and consistent every single time,” Trouchet said.